NSK22215EAE4, can improve the sample picture for the customer

INQUIRY

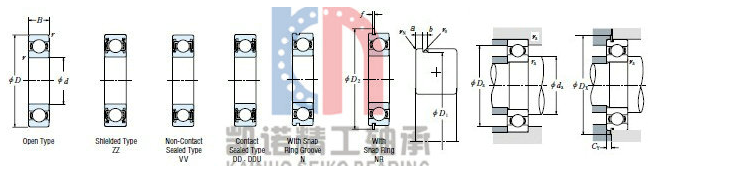

| d(mm) | 75 | da(min) | 84.87 |

| B(mm) | 31 | Db(max) | - |

| D(mm) | 130 | Da(max) | 121.117 |

| C0r | 244000 | Grease | 3400 |

| Cr | 190000 | oil | 4300 |

| ra | 1.5 | cup | 22215EAKE4 |

| New Model | NSK 22215EAE4 | m(kg) | 1.64 |

The steel is heated to the critical point (AC3, ACcm) above, to fully austenitic Hong, then cooled in the air, the heat treatment process, called normalizing.

(a) normalizing process

The heating temperature normalizing is the chemical composition of AC3 above the temperature of 50-100 DEG C; hypereutectoid steel heating temperature above ACcm 30-50 C. The heat preservation time mainly depends on the effective thickness of the workpiece and the kinds of furnaces, heating in the box furnace such as, can the effective thickness of one minute per mm insulation calculation. Insulation after cooling, can generally be cooled in the air, but some large parts or in the high temperature in summer, sometimes using the hair dryer or spray cooling.

(two) and properties of normalized tissue

Normalizing is essentially a special case of annealing. Two different, mainly lies in the cooling speed, subcooling faster, resulting in pseudo eutectoid transformation, so that the organization of pearlescent increased, and the Pearl Dai lamellar spacing is smaller. It should be pointed out, some high alloy steel air cold, can obtain the bainite or martensite, this is because of supercooled austenite in high alloy steels are very stable, C curve.

Due to the characteristics of normalized organization, so the strength, hardness, toughness after normalizing than after annealing is high, and the plastic also did not reduce.

The application of the fire

Normalizing and annealing compared to the mechanical properties of the steel is high, the price increase is simple, short production cycle, less energy consumption, so under the possible conditions, priority should be given to using the normalizing treatment. The following application now:

1 as the final heat treatment of ordinary structural parts

2 to improve the machinability of low carbon steel and low carbon alloy steel

Pre heat treatment 3 as medium carbon structural steel making is the important parts of the.

4 the elimination of hypereutectoid steel stroke like two cementite, make organization for spheroidizing annealing

5 in some large or complicated shape parts, quenching cracking into the dangerous may have, normalizing also often instead of quenching and tempering treatment, as the parts of the final heat treatment. Very * right. At this time has not called normalizing, and called on empty quenching. In order to increase the hardness of low carbon steel, may be appropriate to increase the normalizing temperature.

INQUIRY sales@hellerbearings.com

- Details: NSK22215EAE4, can improve the sample picture for the customer

- Like Model No.:

Hot Model No.: